source:TIANS

source:TIANS date:2024-03-12

date:2024-03-12From March 5th to 7th, the 12th International Bio-Fermentation Exhibition was grandly held in Jinan, the Spring City. More than 560 domestic and foreign exhibitors and over 32,000 professional visitors gathered here. TIANS made a heavy appearance with its new brand positioning as an engineering design group empowering the industrialization of new technologies. Its featured exhibits such as intelligent instantaneous sterilizing equipments, intelligent automatic cleaning machines, full-process automated fermentation technology solutions, synthetic biology industrialization T-EPC full-process services, and engineering consulting and design attracted a large number of industry peers to stop and negotiate, jointly exploring the new future of the bio-fermentation industry.

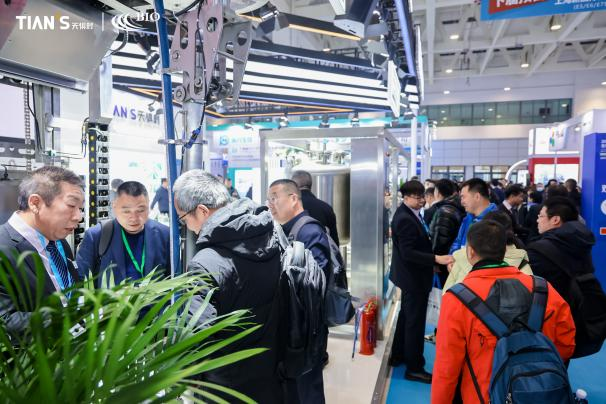

The grand occasion of TIANS's booth at the 12th Jinan International Bio-Fermentation Exhibition

Fermentation Twin Stars: More Energy-Saving, Environmental-Friendly and Intelligent

At this exhibition, TIANS's two star products, the intelligent instantaneous sterilizing equipment and the intelligent automatic cleaning machine, widely spread the concepts of intelligence and greenization.

The intelligent instantaneous sterilizing equipment, rated at the domestically leading level in scientific and technological achievements, adopts the principle of high-temperature instant sterilization. It relies on a high-efficiency heat exchanger with patented technology to realize the simultaneous processes of heating, heat preservation, and cooling, ensuring a sterility rate of up to 99.99%. It can save more than 70% of steam and 90% of cooling water, truly helping enterprises reduce costs and increase efficiency, making sterility achievable at one touch. With a global sales volume of over 100 units (sets), it leads in market share.

Intelligent instantaneous sterilizing equipment

The intelligent automatic cleaning machine is a high-pressure automatic cleaning device widely used for 360° dead-angle-free cleaning inside fermentation tanks and reaction kettles. It has five measures to ensure clean cleaning, with advantages such as high cleaning efficiency, safety, and reliability. It avoids many potential safety hazards when workers enter the tanks and is widely used in industries such as biomedicine, biological materials, medical aesthetics, new energy, and natural health products.

Intelligent Automatic Cleaning Machine

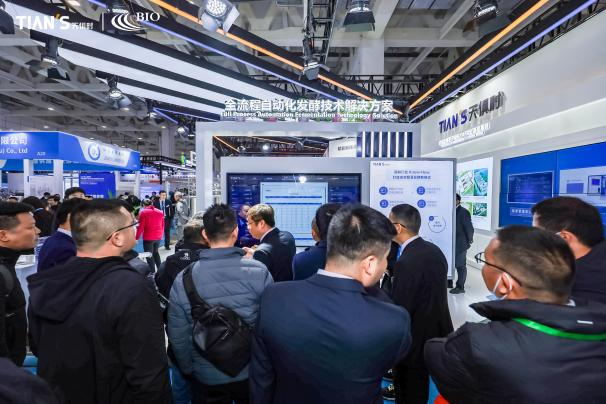

Fully Automated Fermentation: Building Smart Fermentation Factories

TIANS has deeply cultivated industry know-how and can provide full-process automated fermentation technology solutions ranging from fermentation batching, continuous online sterilization of materials, online solid/empty sterilization of fermentation tanks, online sterilization of sterile pipelines, strain cultivation to system cleaning, effectively reducing the contamination rate, saving energy and reducing consumption, and improving product quality and fermentation levels.

The fermentation factory intelligent monitoring platform launched by TIANS at this exhibition integrates functions such as fermentation factory site planning, real-time monitoring of each floor, process flow control, energy management, report analysis, and abnormal early warning. It also uses 3D digital twins to intuitively monitor the operation status of the fermentation factory, accurately control the process flow and production equipment, and help fermentation enterprises achieve lean and digital production operations.

Fermentation Factory Intelligent Monitoring Platform

Synthetic Biology: From Laboratory to Industrialization

As the "third biotechnology revolution", synthetic biology is a key link in biological manufacturing. According to the prediction of the Organization for Economic Cooperation and Development, by 2030, the scale of related industries will reach 35% of the global industrial GDP.

In recent years, TIANS has actively leveraged its own process advantages to create a synthetic biology industrialization T-EPC full-process service covering process technology, pilot-scale amplification, process simulation and optimization, process package compilation, engineering consulting and design, automation and informatization, intelligent equipment, and engineering construction and operation and maintenance. It has been successfully applied to leading synthetic biology enterprises such as Bluepha, Huarheng Biology, Yiduoli Biology, Jinbo Biology, and Chuanning Biology.

Full-Process Capabilities in Synthetic Biology

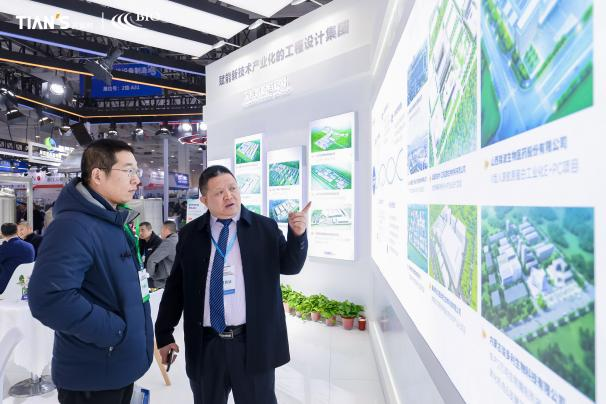

Leading with Design: Drawing a New Blueprint for the Future

As an engineering design group empowering the industrialization of new technologies, TIANS holds Class A qualifications in both the chemical, petrochemical, and pharmaceutical industries and the construction industry. Supported by both a local engineering design institute and a Swiss consulting and innovation center, TIANS's design team not only has cutting-edge international design concepts but also possesses full-process service capabilities from conceptual design to project implementation, ensuring that enterprises' design schemes achieve the optimal balance in investment efficiency, schedule control, and quality standards.

Engineering Consulting and Design Capabilities

Industry Elites Speak Out: Jointly Exploring New Development Trends

Exploring trends and discussing the future together. On March 6th, Li Xiangke, Chief Engineer of TIANS Pharmaceutical and Chemical Engineering Design Company, and Yue Zongli, Chief Technology Officer of TIANS Automation and Informatization, gathered with more than 100 professionals from universities, research institutes, and bio-fermentation enterprises at the "2024 Synthetic Biology and Fermentation Cutting-Edge Technology and Intelligent Equipment Forum" held concurrently with the exhibition to explore the cutting-edge trends in the future development of synthetic biology.

Li Xiangke gave a course sharing themed "Let Dreams Come into Reality: From Synthetic Biology Laboratories to Green Biological Manufacturing Factories". First, he comprehensively introduced the future development direction of the biological manufacturing industry around the connotation, policy progress, and industrialization challenges of synthetic biology, and pointed out that the focus of industrialized production is to reasonably calculate and design fermentation tanks and fermentation processes, optimize process integration and large-scale production technology in the amplification process, improve fermentation levels, and reduce production costs. Then, he introduced the design concepts of synthetic biology factories from the aspects of economy, intelligence, systematization, green environmental protection, and safety, putting forward many constructive ideas for the industrialization of synthetic biology enterprises.

Li Xiangke delivering a keynote speech

Yue Zongli then gave a keynote speech themed "Full-Process Automated Fermentation Technology Solutions". First, he pointed out that in the face of problems such as contamination, complex operation forms, high requirements for automatic control, high energy consumption and high pollution, and high temperature and humidity in the environment, automation and informatization should be considered from key points such as close integration with processes and operations, practicality of control schemes, convenience of operation and maintenance, cost control, installation professionalism, system expandability, and compliance. He also systematically introduced the hierarchical structure of automation and informatization engineering in fermentation factories, full-process fermentation process automation, T-MES intelligent manufacturing execution system, and SCADA and intelligent monitoring platform for full-process automated fermentation factories. Finally, he gave practical application explanations combining TIANS's actual automation and informatization project cases, which benefited everyone a lot.

Yue Zongli delivering a keynote speech

After the speech, Yue Zongli, Chief Technology Officer of TIANS Automation and Informatization, was also invited to participate in a roundtable forum themed "How to Break Through the Bottleneck in the Industrialization of Synthetic Biology", where he conducted in-depth discussions with enterprises such as Qilu Pharmaceutical, Bestzyme Biology, and Manson Biology on issues such as the core elements of the industrialization of synthetic biology and how to cross the capital cycle.

Yue Zongli (third from the right) invited to participate in the roundtable forum

As an engineering design group empowering the industrialization of new technologies, TIANS has actively rooted and continuously expanded in bio-fermentation and synthetic biology in recent years, helping many enterprises achieve the leap from laboratory to industrialization. In the future, TIANS will continue to demonstrate its "technological style" of mastering the future, continuously enhance its strength in the full-process service model of bio-fermentation and intelligent, energy-saving equipment, and jointly create a better future for biological manufacturing.

BOOK

BOOK 中文

中文

Tender Hall

Tender Hall  Resource Center

Resource Center

RETURN

RETURN