source:TIANS

source:TIANS date:2024-11-20

date:2024-11-20Recently, the 20,000-ton annual output bio-enzyme preparation project of Inner Mongolia Yiduoli Biotechnology Co., Ltd. (hereinafter referred to as the "Yiduoli Project"), undertaken by TIANS Group, successfully passed the trial run at one go and received a letter of commendation from the owner. The letter affirmed and praised TIANS's cutting-edge professional technical level and efficient and responsible work style.

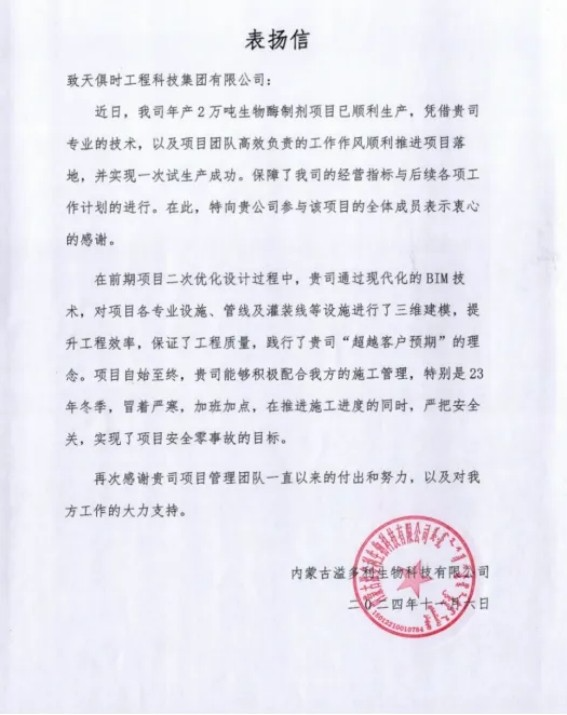

Yiduoli Biology sent a letter of commendation

TIANS is mainly responsible for the mechanical and electrical installation works of the project's fermentation and extraction workshop, public auxiliary workshop, chemical warehouse, chemical tank farm and pump house, and factory pipe gallery, as well as subsequent single-machine commissioning and linkage commissioning. After the project is completed, it will mainly produce feed enzyme preparations, food enzyme preparations, industrial enzyme preparations, etc., which will greatly enhance and strengthen Yiduoli's R&D and production advantages in biological enzymes.

Guangdong Yiduoli Biotechnology Co., Ltd., established in 1991, focuses on the research and development of biological products. It is based on three main businesses: biological enzyme preparations, active natural products, and nutrition and health. It has formed five series of products: biological enzyme preparations, biosynthetic products, plant extracts, functional feed additives, and pet products. It is the largest biological enzyme preparation manufacturer in Asia. As its wholly-owned subsidiary, Inner Mongolia Yiduoli Biotechnology Co., Ltd. was established in 2008, mainly responsible for the production and sales of feed enzyme preparations, food enzyme preparations, and industrial enzyme preparations. It has successively won honorary awards such as Inner Mongolia Autonomous Region Green Factory, Autonomous Region Key Agricultural and Animal Husbandry Leading Enterprise, Autonomous Region-level Enterprise R&D Center, and National High-tech Enterprise.

Inner Mongolia Yiduoli Biotechnology Co., Ltd.

Design Optimization, Empowered by Digital Intelligence

To better optimize the pipeline layout and reasonably plan the construction period, TIANS, combining its digital design capabilities, carried out an overall BIM optimization design for the original workshop, new workshop, reserved workshop, and factory pipe gallery and other facilities in the early stage of the project to ensure the optimal layout and scheme of each workshop. At the same time, for the fermentation workshop, to ensure the sterility rate during the fermentation process and the reasonable and beautiful overall layout of the equipment valve group, the TIANS BIM team reasonably optimized the fermentation tanks, seed tanks, and feeding tanks in the fermentation workshop. According to the process requirements, the layout of air filters and valve groups and the direction of pipelines were optimized to ensure that there are no dead corners in the pipeline layout, meet the fermentation process requirements, and make later operation and maintenance more convenient, improve the overall appearance, and realize what you see is what you get.

BIM model of Yiduoli Project factory area

Process Support, Escorting Product Launch

TIANS has always been committed to enabling the industrialization of new technologies and accelerating the construction of a bridge from the laboratory to industrial reality. In this Yiduoli Project, TIANS's process experts who are well versed in process scaling-up and fermentation principles participated in depth. In terms of process optimization, TIANS's technical experts changed the cooling water system of the fermentation tank and seed tank from series connection to parallel connection, avoiding the possible abnormal tank temperature that affects the normal progress of fermentation production, and at the same time improving heat exchange efficiency and energy utilization; in the process of sterile testing of the production system, through the optimization of the test plan and the reasonable expansion of the sample size for sampling, the normal progress of the system sterile test and the accuracy of the sample sterility test were ensured, avoiding the possible impact of sterile misjudgment on production, and ensuring the orderly progress of production and the high-quality output of products.

The successful completion and successful trial run of the Yiduoli bio-enzyme preparation project at one go not only created a demonstration project for the local area and helped Yiduoli to carry out smooth production, but also reflected the advantages of TIANS Group's T-EPC model led by design and technology. Empowering industries and controlling the future with technology, TIANS will always be led by science and technology to help the smooth implementation of innovative technologies in the field of synthetic biology and create a new future for the industry.

BOOK

BOOK 中文

中文

Tender Hall

Tender Hall  Resource Center

Resource Center

RETURN

RETURN