source:TIANS

source:TIANS date:2024-11-20

date:2024-11-20From November 17th to 19th, the 65th China International Pharmaceutical Machinery Expo (hereinafter referred to as "Pharmaceutical Machinery Expo") was grandly held in Xiamen. This year's expo covered an exhibition area of 234,000 square meters, attracting 1,694 well-known enterprises from 25 countries and regions at home and abroad, and nearly 60,000 professional visitors. As an engineering design group empowering the industrialization of new technologies, TIANS Group depicted a brand-new blueprint for industrialization for the audience with its cutting-edge design concepts, intelligent and green information and automation technologies, and T-EPC full-process services in the pharmaceutical field.

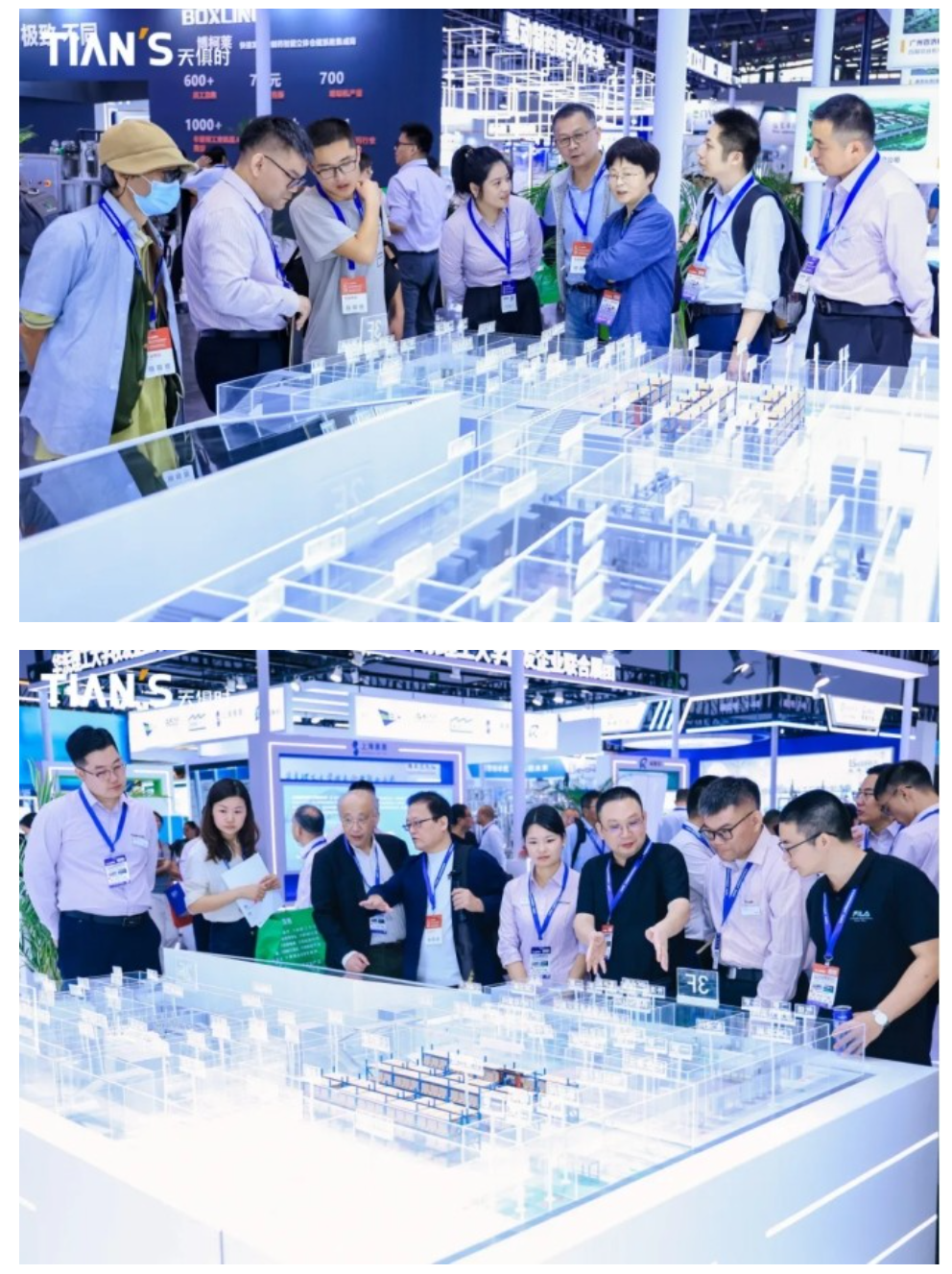

Design + Intuitively Presenting the Future Blueprint

Engineering consulting and design is one of the most important links in the entire life cycle of project construction, and it is also the intellectual core of TIANS's full-process industrialization services. TIANS took the Antibody-Drug Conjugate (ADC) workshop sand table as a model to intuitively display the overall layout of the ADC workshop and the planning and design of the indoor HVAC system, reflecting the design concepts of flexibility, efficiency, energy saving and convenience. In addition, TIANS deeply integrated BIM technology with design, bringing an intuitive presentation to everyone through the comparison of multiple BIM cases and real-scene effects.

Antibody-Drug Conjugate (ADC) Workshop Sand Table

Intelligence + Full-stack Self-developed Digital Factory

Against the background of the rapid development of digital and modern industry and the cross-integration and innovation of emerging technologies, the fourth industrial revolution of intelligent manufacturing, which uses information integration and intelligent control systems to build pharmaceutical digital factories, has arrived. As a comprehensive solution provider for digitalization and informatization in the pharmaceutical industry, TIANS presented T-MES intelligent manufacturing execution system, digital public engineering for biomedicine, production visualization dashboard, full-process automation control of biological fermentation, and automation engineering of chemical synthetic API workshops, offering a feast of wisdom to everyone.

TIANS Group's Automation Dashboard

Sharing + Professional Narration to Discuss the Future

Combining the current development trend of synthetic biology, the Pharmaceutical Machinery Expo held the Synthetic Biology and Biomanufacturing Industry Development Conference for the first time. Li Xiangke, Vice President of the Chemical and Pharmaceutical Design Institute of TIANS Group, was invited to give a sharing on the theme of "PT-EPC Complex Mode Empowering the Industrialization of Synthetic Biology Technology".

He first introduced the difficulties and challenges faced by the industrialization of synthetic biology, including enterprise positioning, product selection direction, financing channels, factory location and technology. Then, Li Xiangke respectively talked about the key points in the industrialization process, such as strain construction, technical route selection, process optimization and equipment selection, from the progressive steps of small-scale trial research and development, pilot-scale amplification and commercial mass production. Subsequently, Li Xiangke emphasized the PT-EPC complex mode, which emphasizes the integration of process technology and design, with process technology experts and design experts as the leading roles, to realize the whole-process system integration and optimization, so as to ensure the success of one-time commissioning. Finally, he said that synthetic biology manufacturing factories will develop towards lean, intelligent, safe and green directions to improve production efficiency and product quality. In the future, TIANS will also promote the industrialization of cutting-edge synthetic biology technologies through the PT-EPC complex mode and construct a new form of industrial upgrading.

Li Xiangke Giving a Sharing

In the technical exchange meeting held during the same period as the Pharmaceutical Machinery Expo, Zhou Lanxia, Vice Chairman of TIANS Group and Dean of the Chemical and Pharmaceutical Design Institute, and Pang Shichong, Director of the Digital Center of the Chemical and Pharmaceutical Design Institute of TIANS Group, gave keynote speeches on "Antibody-Drug Conjugate Production Process and Design Concepts" and "The Key to Digital Factories - Engineering Digital Delivery" respectively.

Zhou Lanxia first explained the composition mode and operation mechanism of ADC drugs, and then gave everyone a more systematic understanding of ADC drugs through the development history, global market scale, various regulations and risk control of ADC drugs. Then, in the production process part, she first explained the production process of ADC drugs, including cell recovery, expansion culture, bioreactor culture and other steps, and discussed the application of single-use technology and closed processes in ADC production. Finally, Zhou Lanxia shared the design of process layout and indoor HVAC system, emphasizing the importance of reasonable design for controlling pollution and avoiding cross-contamination, providing comprehensive and professional industry overview and technical guidelines for professionals in the ADC drug field.

Zhou Lanxia Giving a Sharing

Pang Shichong then discussed in depth with the on-site guests the key role of engineering digital delivery in the construction of digital intelligent factories. He first emphasized the importance of establishing a factory data asset platform, which integrates digital asset models during the construction and operation and maintenance periods, covering the whole-cycle information management from design, procurement, construction to operation and maintenance. Then he said that the core of digital delivery is to shift from taking drawing data as the core to taking equipment and facility information as the core, integrating multiple dimensions such as equipment management and process management, and realizing data integration and real-time operation and maintenance. Finally, Pang Shichong emphasized that digital delivery promotes a safer and more efficient factory operation mode, providing a practical basis for the audience to understand the upgrading of the digital industrial structure.

Pang Shichong Giving a Sharing

As an engineering design group empowering the industrialization of new technologies, TIANS is committed to providing customers with full-process services from technology research and development, engineering consulting and design to engineering general contracting, automation and informatization, and intelligent equipment, helping customers realize the industrialization transformation from Lab to Fab and accelerating the implementation of new technologies. At present, it has provided excellent T-EPC services for leading enterprises in the fields of synthetic biology, biomedicine and chemical pharmaceuticals, such as Qilu Pharmaceutical, Chuanning Biology, Huaheng Biology, Bluepha, CECEP Wanrun, BeiGene and Hepalink.

TIANS Group's Booth

Accelerating the implementation of innovative technologies and making blueprint concepts visible. Since its establishment, TIANS has always been led by science and technology, deeply engaged in the pharmaceutical field, and created a unique T-EPC general contracting service model with process technology and design concepts. In the future, TIANS will continue to deepen its technological foundation, transform more advanced technologies in the pharmaceutical industry into high-quality projects, and create an industrial future with technology.

BOOK

BOOK 中文

中文

Tender Hall

Tender Hall  Resource Center

Resource Center

RETURN

RETURN