source:TIANS

source:TIANS date:2024-10-26

date:2024-10-26On October 26th, the "Addressing Both Symptoms and Root Causes in Fine Chemicals" — 2024·6th Young Designers 50 Forum, co-hosted by TIANS Group and the China Pharmaceutical Engineering Design Association, was successfully held at the headquarters of TIANS Group. More than 50 young designers from over 20 chemical industry design institutes, including China Huanqiu Contracting & Engineering Corporation, Wuhuan Engineering Co., Ltd., Sinopec Shanghai Engineering Co., Ltd., Saidi Engineering Co., Ltd., China National Pharmaceutical Group United Engineering Co., Ltd., Zhejiang Engineering Design Co., Ltd., Chongqing Pharmaceutical Design Institute, Jilin Pharmaceutical Design Institute, and Tianzheng Design Institute, shared cutting-edge knowledge, wisdom, and ideas at this forum.

This forum focused on the field of fine chemicals, where designers discussed cutting-edge design issues around two hot topics: fire safety standards and intrinsic safety in this field. The forum was hosted by Mr. Wu Shaohua, Director and Chief Designer of TIANS Group.

Wu Shaohua hosting the forum

Elites Gather to Launch the Design Chapter

At the beginning of the meeting, Miao Bu, Deputy Secretary-General of the China Pharmaceutical Engineering Design Association, and Xue Long, Chief Engineer of TIANS Group, delivered welcome speeches on behalf of the organizers.

Miao Bu stated that young designers should gain a deep understanding of the internal connections among the four specifications in the fine chemical field through this forum and familiarize themselves with their concepts and specific terms. He then shared his insights on issues such as the future development positioning and career planning of young designers present, based on his personal experience. He believed that everyone could establish deeper connections through the platform of the Young Designers 50 Forum and jointly promote the development of the industry.

Miao Bu delivering a welcome speech

Subsequently, Xue Long delivered a speech on behalf of the organizer. He mentioned that TIANS Young Designers Forum was upgraded to the Young Designers 50 Forum this year, aiming to better provide a more professional and open communication platform for young elite designers in the industry, and jointly promote innovation and development in the engineering design industry. Currently, while the fine chemical industry is developing rapidly, it also faces many challenges, requiring young designers to continuously explore the essence, attach importance to safety, and promote industrial development. He hoped to hear more insightful views on technological innovation and industry development through this forum, thereby breaking technical barriers and exploring the future of design together.

Xue Long delivering a welcome speech

Safety First, Harmonizing a Symphony of Wisdom

Guided by standards and specifications, and based on intrinsic safety. In this forum, Liu Yuan, a senior expert from China National Pharmaceutical Group United Engineering Co., Ltd., Hu Chen, a safety expert from Sinopec Engineering Construction Co., Ltd., and Li Wenfeng, Chief Safety Officer of TIANS Group, jointly brought a feast of ideas.

Mr. Liu Yuan first gave a systematic explanation on the theme of "Several Issues in the Implementation of the 'Code for Fire Protection Design of Fine Chemical Enterprises'". He introduced the formulation principles and characteristics of the standard through the setting principles of fire separation distances. Then, based on the "Standardization Law of the People's Republic of China", he elaborated on the relationship between this standard and other standards and regulatory documents, discussed the classification and scope of application of fine chemical products, emphasized that the fire protection design of fine chemical enterprises should comply with the provisions of current national standards, and interpreted the applicability of the "Guidelines for Safety Risk Prevention and Control of Hazardous Chemical Production and Construction Projects (Trial)". In the implementation of the standard, Mr. Liu Yuan sorted out 16 typical cases, including the definition of tank farm volume, the implementation of fire protection design for phased projects, and the selection of design standards for projects without flammable and explosive materials, providing clear guidance and in-depth analysis for the fire protection design of fine chemical enterprises.

Mr. Liu Yuan sharing on the theme of "Several Issues in the Implementation of the 'Code for Fire Protection Design of Fine Chemical Enterprises'"

Ms. Hu Chen started from intrinsic safety and took "Intrinsic Safety Design of Chemical Construction Projects" as the theme, enabling everyone to have a deeper understanding of intrinsic safety. She introduced the origin and development of the concept of intrinsic safety by taking the explosion accident at the Flixborough chemical plant in the UK as an example. Through the four core principles of intrinsic safety — minimization, substitution, mitigation, and simplification — she stated that reducing the use of hazardous substances, adopting safer materials, and optimizing process flows can effectively reduce the risk of accidents. Ms. Hu Chen systematically analyzed topics such as setting up "intrinsically safer" protection layers and how to achieve "intrinsically safer" design. She proposed that it is necessary to establish the concept of "intrinsically safer" design and integrate safety thinking in the early stage of design; strengthen "intrinsically safer" process design, apply the principles of intrinsic safety in the process research and development stage, and throughout the entire life cycle of the project; optimize the "intrinsically safer" control system, maintain the consistency of the control system and the intrinsic safety of ergonomics, emphasizing the great significance of ergonomics.

Ms. Hu Chen sharing on the theme of "Intrinsic Safety Design of Chemical Construction Projects"

Mr. Li Wenfeng shared content related to "Application of Reaction Safety Risk Assessment in Intrinsic Safety Design". In his sharing, he pointed out that China's chemical industry has an unbalanced overall development, facing problems such as poor safety awareness, insufficient safety management capabilities, uneven design levels, and low automation. Then, Mr. Li Wenfeng detailed the standards for reaction safety risk assessment, as well as key terms and parameters in "GB/T42300-2022 Specification for Safety Risk Assessment of Fine Chemical Reactions", and explained how to use these assessment tools to optimize process parameters and reduce the level of process hazard. Later, he shared the application of reaction safety risk assessment in practice, and through multiple examples, described how to formulate effective safety measures based on assessment results, and how to reduce risks through process optimization. He also explained the calculation methods of safety measures such as emergency pressure relief and quenching for reaction runaway in combination with different process hazard levels. The participants gained a lot from this sharing, and it is believed that it will further help enterprises achieve comprehensive risk control from the source to the production process and improve the intrinsic safety level of the industry.

Mr. Li Wenfeng sharing on the theme of "Application of Reaction Safety Risk Assessment in Intrinsic Safety Design"

First Establishment, Gathered Strength for Development

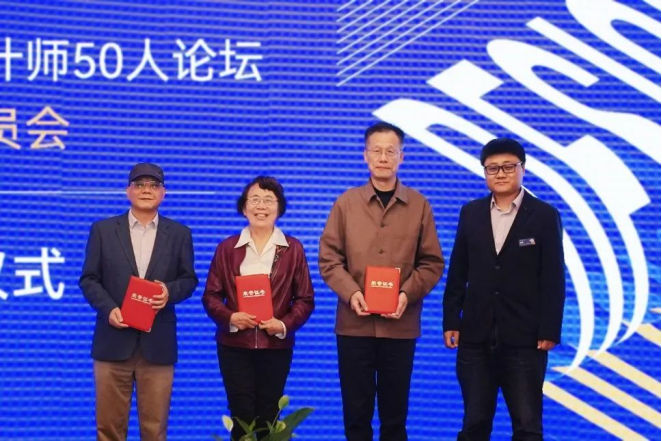

To better build an industry technical exchange platform and assist the growth of young designers, the Expert Committee of the Young Designers 50 Forum was officially established at this forum. Three industry experts, namely Mr. Miao Bu, Deputy Secretary-General of the China Pharmaceutical Engineering Design Association, Mr. Liu Yuan, Senior Expert of China National Pharmaceutical Group United Engineering Co., Ltd., and Ms. Hu Chen, Safety Expert of Sinopec Engineering Construction Co., Ltd., were selected as the first batch of experts in the Expert Committee. In the future, the Expert Committee of the Young Designers 50 Forum will provide forum participants with cutting-edge scientific and technological information, advanced design concepts, and mature technical solutions through academic exchanges, technical consulting, and research projects, contributing to the progress and development of the industry.

The Expert Committee of the Young Designers 50 Forum was officially established

Elite Dialogue, Discussing Industry Trends

Pooling wisdom and sharing achievements. This Young Designers 50 Forum is not only a platform for outputting cutting-edge knowledge but also a shared platform for young designers to communicate, discuss, learn, and make progress. To this end, the forum set up two elite dialogue sessions, morning and afternoon, allowing young designers to fully solve doubts and problems in daily work, and also enabling them to establish industry connections, promoting the rapid development of the engineering design field in the fine chemical industry.

In the morning elite dialogue session, participants conducted a detailed analysis around fine chemical-related standards and specifications. In the afternoon elite dialogue session, young designers conducted in-depth discussions in group discussions on issues such as full-process automated design of hazardous chemical processes, general layout planning of high-value-added fine chemical enterprises, the application of fine chemical industry specifications, and how design institutes connect projects from laboratory to industrialization, and carried out systematic sharing and exchanges.

Each group conducting scheme discussions

After in-depth exchanges and discussions in the elite dialogue session, Gao Chuanqi, Deputy Director of the Process Design Office of China National Pharmaceutical Group United Engineering Co., Ltd., and Tian Kaihua, Deputy Chief Engineer of the Chemical and Pharmaceutical Design Institute of TIANS Group, finally won the title of Elite Designer with their cutting-edge thinking, rigorous logic, and wonderful speeches. Their Group 6 was also rated as the Elite Design Group by unanimous approval of experts due to the team's thinking, fluent expression, and highly innovative and feasible design schemes.

Award ceremony

The Future is Here, Sharing Cutting-Edge Technologies

As a characteristic part of the Young Designers 50 Forum, "Good Technology Promotion" selects the most cutting-edge process technologies and intelligent products for promotion and introduction every year. This time, Yao Zhenyong, Chief Engineer of TIANS Dry Sugar-Making Technology Company, brought "Sharing on Corn Dry Separation Sugar-Making Process Technology".

Yao Zhenyong first introduced the current situation of using corn wet sugar-making technology, as well as problems such as high investment, low conversion rate, high cost, and low value of by-products. Then, he introduced that corn dry sugar-making technology can maximize the yield of endosperm, extract all germ, and minimize the yield of corn bran, thereby efficiently separating corn protein powder and producing high-quality glucose syrup. Moreover, under the same output, the investment in dry method is significantly reduced, and the production and operation cost is 1/5 of that of the wet method. Finally, he stated that corn dry separation sugar-making technology is a representative technology of new productive forces in the corn deep processing industry, a revolutionary, innovative, and sustainable technology, which will bring new changes and development opportunities to the corn deep processing industry.

Yao Zhenyong delivering the "Sharing on Corn Dry Separation Sugar-Making Process Technology" for good technology promotion

Design leads industry transformation, and elites gather to discuss development. In the future, TIANS Young Designers 50 Forum will continue to focus on cutting-edge industries, grasp the front-end trends, take design as the lead, provide a high-end platform for open communication for young designers, and empower the intelligent transformation and sustainable development of modern industry.

BOOK

BOOK 中文

中文

Tender Hall

Tender Hall  Resource Center

Resource Center

RETURN

RETURN