source:Marketing

source:Marketing date:2025-09-19

date:2025-09-19In early autumn in Yumen, the snow line is already visible atop the Qilian Mountains, and strong winds sweep sand grains across the poplar treetops on the Gobi Desert. On this land deepening with autumn hues, the Section 3 EPC project of the Gansu Juhua High-Performance Silicon-Fluorine New Materials Integrated Project, undertaken by TIANS Group, is advancing efficiently under Juhua Group's strategic vision of "Orderly Planning, Advanced Base, First-Class Enterprise" and the "June 30th" milestone target. Leveraging the comprehensive advantages of EPC turnkey management, TIANS is progressing design, procurement, and construction in parallel, rapidly completing multiple project milestones with overall progress consistently ahead of schedule.

With a total investment of 41 billion yuan, this project represents the largest industrial investment in Gansu Province's history. It encompasses production systems for industrial silicon, polysilicon, and fluorine-containing polymers, along with supporting facilities such as methane chloride and hydrofluoric acid plants. The project is constructed in two phases, with the first phase scheduled for completion by June 30, 2026. Upon completion, it will significantly propel the domestic substitution of high-performance silicon-fluorine new materials and enhance national self-sufficiency capabilities for strategic supplies.

As the consortium leader, TIANS Group, in partnership with Shanghai Installation Engineering Group, is responsible for the Section 3 EPC project. This includes design, process technology, procurement, construction, and commissioning. Key project units comprise the fluorine-containing resin plant, Fluoropolymer Substations No. 2 and 3, the solid product storage and transportation system, and the auxiliary agent tank farm. Since commencing site operations in Yumen's old urban area on April 17, TIANS has rapidly mobilized resources, initiated construction preparations, and coordinated with stakeholders, with full-scale construction launching in May. To date, civil works for all units are being organized around the clock to meet the "September 30th" handover target. Critical progress includes the post-processing building under construction up to the fourth floor, the polymerization plant achieving roof closure on September 16, and Control Room No. 3 completing structural topping-out on July 11.

Ensuring Efficient Construction with Technical Prowess

The project officially commenced construction in May 2025. Facing multiple challenges including a harsh natural environment, tight schedules, and ongoing process optimizations, the TIANS Gansu Juhua Project Command has consistently upheld "successful first-time commissioning" as its paramount goal. It maximizes the advantages of its integrated "Trinity, Triple-Drive" operational model, ensuring seamless collaboration and efficient synergy among design, procurement, and construction teams. In the design phase, the team employs a "phased drawing release" strategy—submitting excavation, foundation, and main structural drawings sequentially based on urgent construction needs. This ensures continuous on-site workflow while rigorously maintaining the quality of each deliverable, laying a solid foundation for the final system's smooth operation. To address challenges like complex process equipment parameters and stringent selection criteria, the company has deployed technical experts, designers, and procurement engineers for long-term on-site support. Working closely with the client, they precisely finalize process parameters and expedite the selection and procurement of critical equipment, enforcing strict quality control and risk mitigation from the source. This comprehensive approach ensures smooth installation and commissioning in later stages, aiming to achieve the dual objectives of "collaborative for the June 30th target and successful first-time commissioning."

The TIANS Gansu Juhua Project Command actively coordinates with all stakeholders, including local government departments, the client's command center, client business divisions, management companies, and supervision companies. It oversees the overall progress and rhythm of process design, equipment procurement, and construction, ensuring the orderly advancement of all tasks.

Building a Model Project and Setting Quality Standards

In constructing the Gansu Juhua New Materials Project, TIANS has consistently regarded creating an industry benchmark as a core project management objective. From the outset, it has adhered to the principles of "high-standard planning, high-quality construction, and high-level management," comprehensively promoting standardized, refined, and construction practices.

Based on a shared commitment to engineering quality, Gansu Juhua Group highly endorsed TIANS's proposal to establish a quality model display area, with TIANS taking full responsibility for its implementation. The physical display showcases key construction sequences such as foundation structures, equipment installation, pipeline welding, anti-corrosion, and insulation. These models not only clarify construction techniques and quality acceptance standards but also serve as a visual reference for unifying technical standards, construction methods, and quality requirements among all personnel, effectively mitigating quality discrepancies and rework risks. Simultaneously, the project department actively introduced digital management tools, utilizing QR codes to display construction plans, technical disclosure records, and quality control points in real-time, enabling full-process quality traceability, monitoring, and evaluation.

These initiatives have not only laid a robust foundation for overall project quality control but have also provided valuable practical experience in promoting the standardization and development of the fine chemicals construction industry, fully demonstrating TIANS's professional expertise and sense of responsibility in engineering construction.

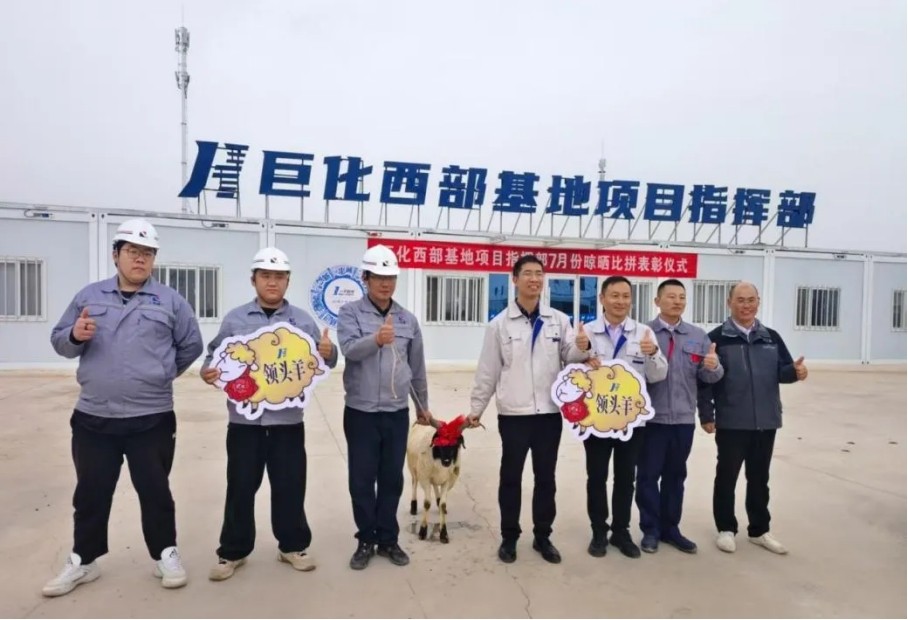

With professional technical capabilities and mature teamwork, TIANS was recognized as the third-place top performer in the June performance ranking, first place in July, and second place in August, demonstrating its solid capabilities through action.

Cultural Integration and Inheriting the Iron Man Spirit

Yumen, the cradle of China's petroleum industry, has nurtured the invaluable "Iron Man Spirit." The TIANS Gansu Juhua Project Command organized visits to the Iron Man Wang Jinxi Memorial Hall, deeply studying the pioneering spirit of "overcoming challenges and pushing forward against all odds."

Project members have deeply integrated this "Iron Man Spirit" with TIANS's own "Iron Army Will" into the project work. Overcoming the harsh Gobi Desert environment, team members worked tirelessly on the front lines under tight schedules and heavy workloads, demonstrating the responsibility and commitment of a new generation of builders. This deep integration of spirit and culture has provided powerful motivation for the project team to maintain efficient progress under challenging natural conditions.

During the construction period, senior leaders of Juhua Group visited the Section 3 project site on multiple occasions for inspection and guidance. On June 23, 2025, Zhou Liyang, Chairman of Juhua Group, visited the site. On August 4, Li Jun, General Manager of Juhua Group, and Tang Yang, Deputy General Manager of Juhua Group and Executive Director/General Manager of Gansu Juhua New Materials Co., Ltd., led another team to inspect Section 3, expressing full affirmation of the project's progress.

From Quzhou, Zhejiang to Yumen, Gansu, since partnering with Juhua, TIANS has consistently leveraged its process technology advantages, using flexible and professional project management as an anchor to deliver one exemplary, benchmark project after another. Moving forward, TIANS will continue to uphold the service philosophy of "exceeding customer expectations," advancing project construction with higher standards and stricter requirements. It is committed to ensuring high-quality and efficient delivery, creating value for clients, and contributing professional strength to the development of the national new materials industry and the industrial rise of Western China.

BOOK

BOOK 中文

中文

Tender Hall

Tender Hall  Resource Center

Resource Center

RETURN

RETURN