source:TIANS

source:TIANS date:2025-12-12

date:2025-12-12On October 14th, the 2023 • 5th Youth Designers Forum in the Pharmaceutical Industry, co-hosted by TIANS Group and the China Pharmaceutical Engineering Design Association, was successfully held at the headquarters of TIANS Group. More than 50 young designers from over ten pharmaceutical industry design institutes, including Chongqing Pharmaceutical Design Institute, Information Industry Electronic The 11th Design and Research Institute, Tianzheng Design Institute, and Sinopec Shanghai Engineering Co., Ltd., gathered here to outline a new blueprint for the development of pharmaceutical engineering design.

The 2023 · 5th Youth Designers Forum in the Pharmaceutical Industry Opens

This forum, themed "Continuous Manufacturing, Empowering the Future", focused on the core topic of "process design for continuous manufacturing" and provided comprehensive explanations from pharmaceutical sub-fields such as fermented APIs, synthetic APIs, solid preparations, and biopharmaceuticals. The forum was hosted by Wu Shaohua, Chief Designer of TIANS Group and Deputy General Manager of the Pharmaceutical and Chemical Engineering Design Company.

Wu Shaohua Hosts This Forum

Doors Open for You — Opening Speech

At the beginning of the forum, Ms. Huang Ji, Secretary-General of the China Pharmaceutical Engineering Design Association, and Mr. Li Xiangke, Director, Vice President of TIANS Group and General Manager of the Pharmaceutical and Chemical Engineering Design Company, delivered welcome speeches respectively.

Huang Ji stated that continuous manufacturing technology has attracted much attention because it can not only reduce industrial pollution but also save costs and avoid safety issues in the production process. She hoped that through this forum, we could work with colleagues to grasp the industrial pulse of continuous manufacturing, green and low-carbon, and apply more cutting-edge design concepts to future pharmaceutical engineering.

Ms. Huang Ji Delivers a Speech at the Forum

Li Xiangke said that during the "14th Five-Year Plan" period, a new round of technological transformation and cross-border integration in the pharmaceutical industry is accelerating. As practitioners in the pharmaceutical industry, we should constantly explore the development trends and apply cutting-edge design concepts to pharmaceutical engineering. The Youth Designers Forum in the Pharmaceutical Industry aims to provide an open communication platform for professional design and technical personnel, disseminate cutting-edge scientific and technological information, improve technical levels, strengthen cooperation, and promote industry development.

Li Xiangke Delivers a Speech at the Forum

Discussing the Future — Sharing Cutting-Edge Knowledge

In this forum, four renowned experts in the pharmaceutical industry jointly brought a feast of knowledge.

Li Xiangke, Director, Vice President of TIANS Group and General Manager of the Pharmaceutical and Chemical Engineering Design Company, first gave a keynote speech on "Application of Continuous Production Processes in the Fermentation Industry". He first explained the process types and characteristics of the fermentation industry from traditional fermentation to fermentation engineering and then to synthetic biology at the current stage. Then he combined the new technology of continuous manufacturing with scenarios such as batching, sterilization, fermentation culture, and extraction and purification, and introduced in detail the required equipment and principles. Finally, he put forward the design concepts of green, intelligent, and lean in the pharmaceutical industry one by one, which benefited the forum guests a lot.

Li Xiangke Gives a Keynote Speech on "Application of Continuous Production Processes in the Fermentation Industry"

Ma Bing, Founder and Chairman of Shanghai Huihe Huade Biotechnology Co., Ltd., gave a keynote speech on "Analysis of Continuous Manufacturing of Chemical APIs". He first made a comparative analysis of continuous flow technology based on different reactor types, and focused on introducing the principle, advantages, and disadvantages of microchannel reactors. He pointed out that micro-reaction has obvious advantages in intrinsic safety, automation improvement, and floor space. However, for some reactions, there are certain problems in yield improvement, energy conservation, and environmental protection, which corrected people's traditional cognition. Then Mr. Ma Bing systematically introduced drug continuous manufacturing technology from various technical types such as reactors, separation, detection, control, and scaling up, answering many puzzles for everyone.

Ma Bing Gives a Keynote Speech on "Analysis of Continuous Manufacturing of Chemical APIs"

Qi Jianming, General Manager of Suzhou Shiping Pharmaceutical Technology Co., Ltd., gave a course sharing on the theme of "Design of Continuous Production of Oral Solid Preparations". He introduced the compliance and conceptual definition of continuous manufacturing, explained the difference between partial continuity and full-process continuity, and detailed the compliance requirements of each step in combination with ICH and GMP. Later, Mr. Qi Jianming analyzed the production core of continuous manufacturing from material pretreatment, feeding and mixing, wet granulation, tableting, coating, and equipment selection, which inspired the majority of designers participating in this forum.

Qi Jianming Gives a Speech on "Design of Continuous Production of Oral Solid Preparations"

Xia Xu, Senior Industry Development Expert of Cytiva, gave a keynote speech on "Opportunities and Challenges of Continuous Production in Biopharmaceuticals". He respectively explained the development trend of biomedicine, the platform construction and operation challenges of biological continuous manufacturing technology, and elaborated on how to build perfusion technology, affinity capture, and Feed Batch. In addition, he looked forward to the advantages of future biopharmaceutical factories through data. He said that although continuous manufacturing technology will greatly improve the production efficiency of biological products, reduce costs and increase efficiency, the real implementation of the technology needs to be reasonably selected in combination with local regulatory requirements, so that this new technology can truly empower the development of the industry.

Xia Xu Gives a Keynote Speech on "Opportunities and Challenges of Continuous Production in Biopharmaceuticals"

Researching New Trends Together — Elite Dialogue

In this Youth Designers Forum in the Pharmaceutical Industry, an elite dialogue session was specially set up to target and solve the problems encountered by designers in their actual work. The guests participating in the forum spoke freely and discussed many issues such as the prospect of continuous manufacturing of traditional Chinese medicine, full automatic control of the fermentation process, and continuous control of nitrification workshops, which aroused wide resonance.

Guests Communicate Extensively in the Elite Dialogue Session

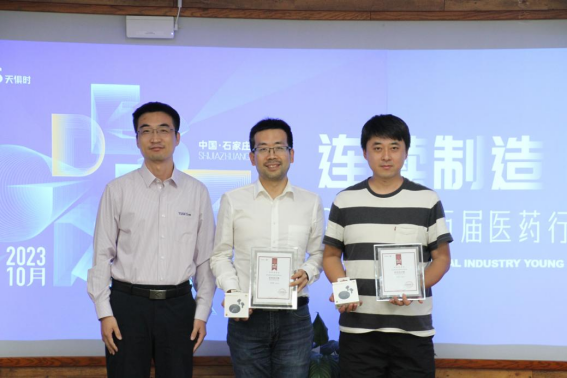

In the end, Kang Wei from Sinopharm Group Chongqing Pharmaceutical Design Institute Co., Ltd., Song Yang from Information Industry Electronic The 11th Design and Research Institute Technology Engineering Co., Ltd., and Chen Nan from Zhejiang Tianzheng Design Engineering Co., Ltd., three outstanding designers, won the title of Elite Designer for their cutting-edge thinking and wonderful speeches in the elite dialogue session.

Li Xiangke Awards the Elite Designer Winners

Green Good Technology — Strong Promotion

"Good Technology Promotion" is a new characteristic session of the Youth Designers Forum, which will select cutting-edge new technologies and products in the industry for promotion. This good technology promotion session was brought by Chen Xiaofei, Deputy Director of TIANS Group's Chen Ping Laboratory, with "New Catalytic Oxidation Technology and Equipment for Pretreatment of High-Concentration Pharmaceutical Wastewater".

Chen Xiaofei said that high-concentration pharmaceutical wastewater has high organic matter concentration, high biological toxicity, complex composition, high inorganic salt content, and poor biochemical treatment effect, which is not only a current difficulty in the industry but also a focus of technical research. Against this background, TIANS Group's Chen Ping Laboratory has developed homogeneous ultraviolet catalytic oxidation technology based on existing technologies such as photocatalytic oxidation in the market; combined with the current continuous manufacturing technology, it has developed continuous pipe flow thermal catalytic oxidation technology, continuously promoting the development of the industry.

Chen Xiaofei Shares "New Catalytic Oxidation Technology and Equipment for Pretreatment of High-Concentration Pharmaceutical Wastewater"

Seeking cutting-edge trends and researching industry development. In the past five years, continuous manufacturing technology has been continuously penetrating into the pharmaceutical industry, and technological innovations time and again have made continuous manufacturing technology well adapt to all links of pharmaceutical production. It is believed that this "Continuous Manufacturing Empowering the Future" Youth Designers Forum in the Pharmaceutical Industry will not only bring cutting-edge knowledge to the majority of industry personnel but also take this opportunity to continuously improve everyone's technical strength and provide strong support for the progress of the pharmaceutical industry.

BOOK

BOOK 中文

中文

Tender Hall

Tender Hall  Resource Center

Resource Center

RETURN

RETURN